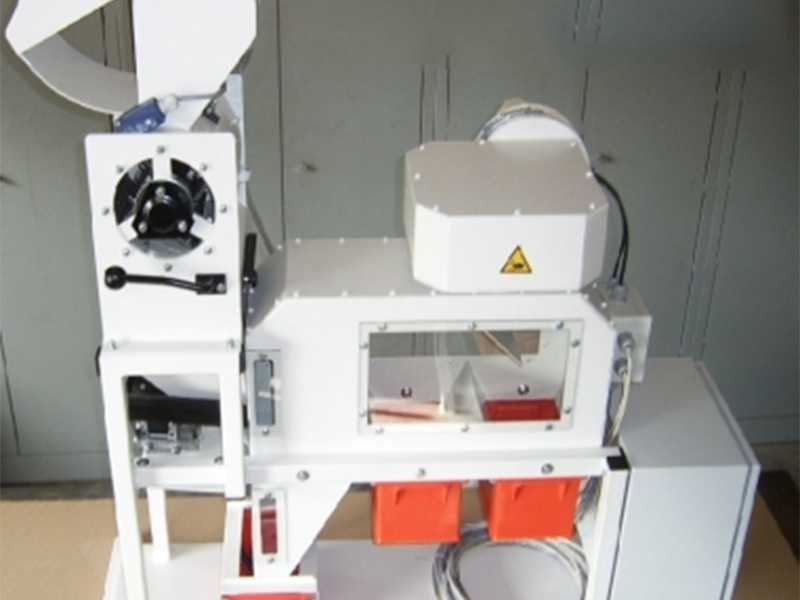

Laboratory Seed Thrasher Type Mini 40

Treatment and purification of single plant.

The ears are inserted from the top into the safety funnel of the thresher / grinder. When closing the flap, the ears automatically fall into the thresher chamber. Here, grains, awns, husks and spindle are detached from each other.

The intensity of this threshing process is dependent on the speed of the thresher rotor, the speed of which is infinitely variable.

After actuation of the bottom flap, the thus resolved ear parts fall into the vibrating chute and are then fed evenly to the air stream of the ascending sifter (infinitely variable).

Here, a separation into light and heavy parts and dust as well as spelled parts are deposited and collected in the expansion chamber.

The Sifter Mini 40 is also suitable as a sifter for all types of crops without an ear follower and is ideal for use in the laboratory for the processing of small samples (up to 100 - 1000g).

| Binbrook Hill |

| Binbrook |

| LN8 6BL |

| Lincolnshire |

| +44 (0)1472 398 498 |

| Copyright © Nickerson Brothers Ltd. 2026 All rights reserved |

| Company No. 01935311 |